At MDT, we specialize in manufacturing custom stamping dies tailored to meet your specific tooling needs. Our team of experts ensures each die is designed with precision and built to deliver exceptional performance, even in the most demanding applications.

Key Considerations for MDT’s Metal Stamping:

- Precision Design: Our stamping dies are accurately designed for consistent and reliable results.

- Durability: We use high-quality materials and superior craftsmanship to prevent premature wear and extend the life of our dies.

- Efficiency: Our processes are optimized for high-volume production, ensuring cost-effectiveness and rapid turnaround times.

By choosing MDT for your metal stamping and custom die manufacturing needs, you benefit from our commitment to quality, precision, and efficiency, ensuring the success of your projects.

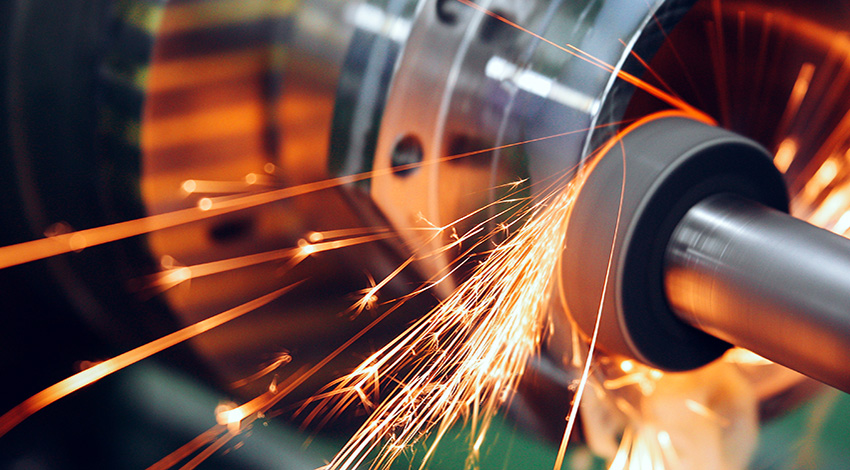

What are Electrical Discharge Machining (EDM) Services?

Electrical Discharge Machining (EDM) services use controlled electrical sparks to precisely remove material from a workpiece, ideal for creating highly intricate and precise parts from hard-to-machine materials like hardened steel, carbide, and conductive composites.

EDM Services at MDT

At MDT, our advanced EDM services excel in:

- Machining Hard Materials: Perfect for materials with high hardness or strength that are difficult to process with conventional methods.

- Creating Complex Shapes: Ideal for intricate geometries, cavities, narrow slots, and sharp internal corners without mechanical cutting forces.

- Ensuring High Accuracy and Surface Finish: Provides exceptional accuracy and surface quality, meeting tight tolerances and high-quality standards.

- Minimizing Mechanical Stress: As a non-contact process, EDM reduces the risk of distortion or damage to delicate parts.

- Handling Low-Volume Production: Efficiently supports custom or limited-edition parts